METAL STRUCTURE FOR

HUNTING FEEDERS PT. 2

METAL STRUCTURE FOR

HUNTING FEEDERS PT. 2

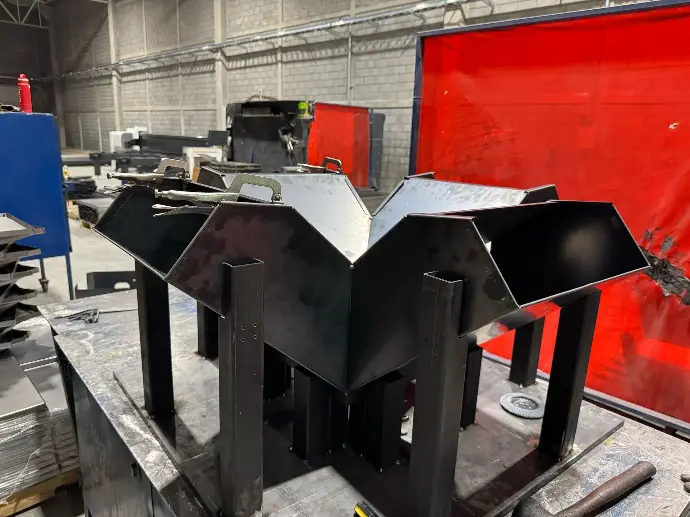

We manufactured a complex metal structure for a U.S. client in the retail sector, which required high precision in cutting, bending, and welding. The project encompassed everything from design to the final product ready for mass distribution.

CONTEXT

This client, with a national presence in the U.S., needed a supplier in Mexico with technical capability and flexibility to develop a new metal product with high dimensional requirements. The production had to meet commercial standards and adapt to its national distribution network.

DEVELOPMENT

The product design was developed in collaboration with our engineering team, optimizing geometries and processes to ensure efficient and precise manufacturing. Advanced technologies such as tube laser cutting, CNC bending, and robotic welding were utilized. Due to the complexity of assembly, specific welding jigs were developed to guarantee repeatability and tight tolerances. Additionally, we expanded our storage capacity to handle the required production volumes, ensuring timely deliveries and optimal conditions.

DELIVERY

The client received a high-quality product, ready for distribution in over a thousand points of sale. Precision, collaborative design, and our ability to adapt infrastructure reinforced the client's trust in our operation as a strategic partner.