SERVICES

We turn ideas into quality solutions, adapting to various industries with a commitment to excellence, innovation, and punctuality.

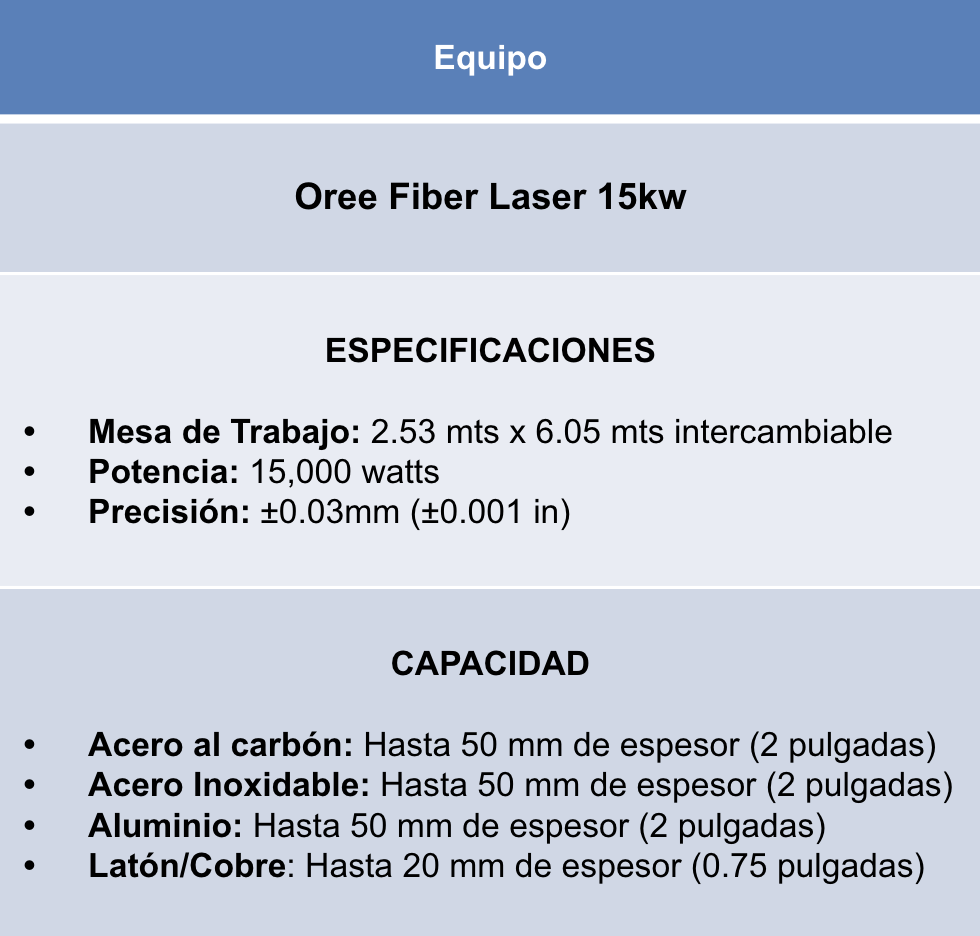

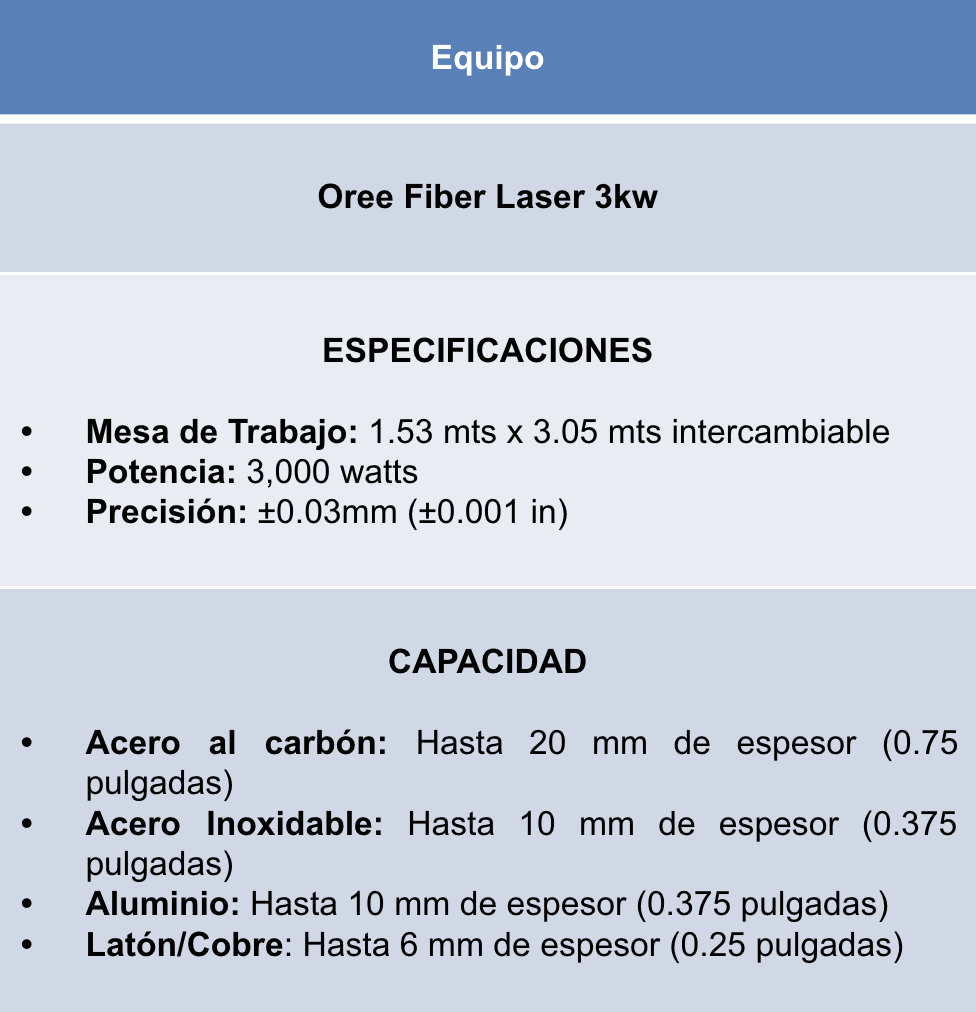

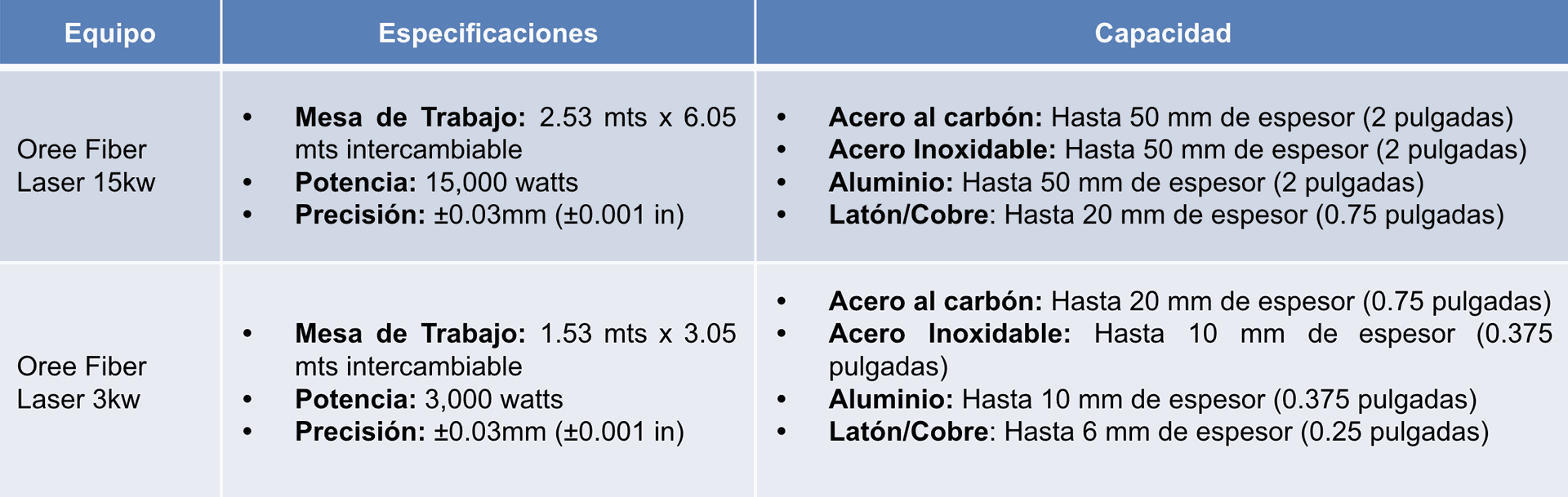

LASER CUT

We have advanced technology such as Fiber Laser Cutting, ideal for cutting prototypes or high-demand products. In addition, we carry out the assembly of fasteners in sheet metal and have extensive experience in the design, manufacturing, and maintenance of stamping tools. Thanks to our network of commercial partners specialized in finishes such as powder coating, anodizing, and electropolishing, we can deliver fully finished parts ready for sale or final assembly.

Además, realizamos el ensamble de tornillería en chapa metálica y contamos con una amplia experiencia en el diseño, fabricación y mantenimiento de herramentales de estampado. Gracias a nuestra red de socios comerciales especializados en acabados como pintura en polvo, anodizados y electropulido, podemos entregar piezas completamente terminadas y listas para su venta o ensamblaje final.

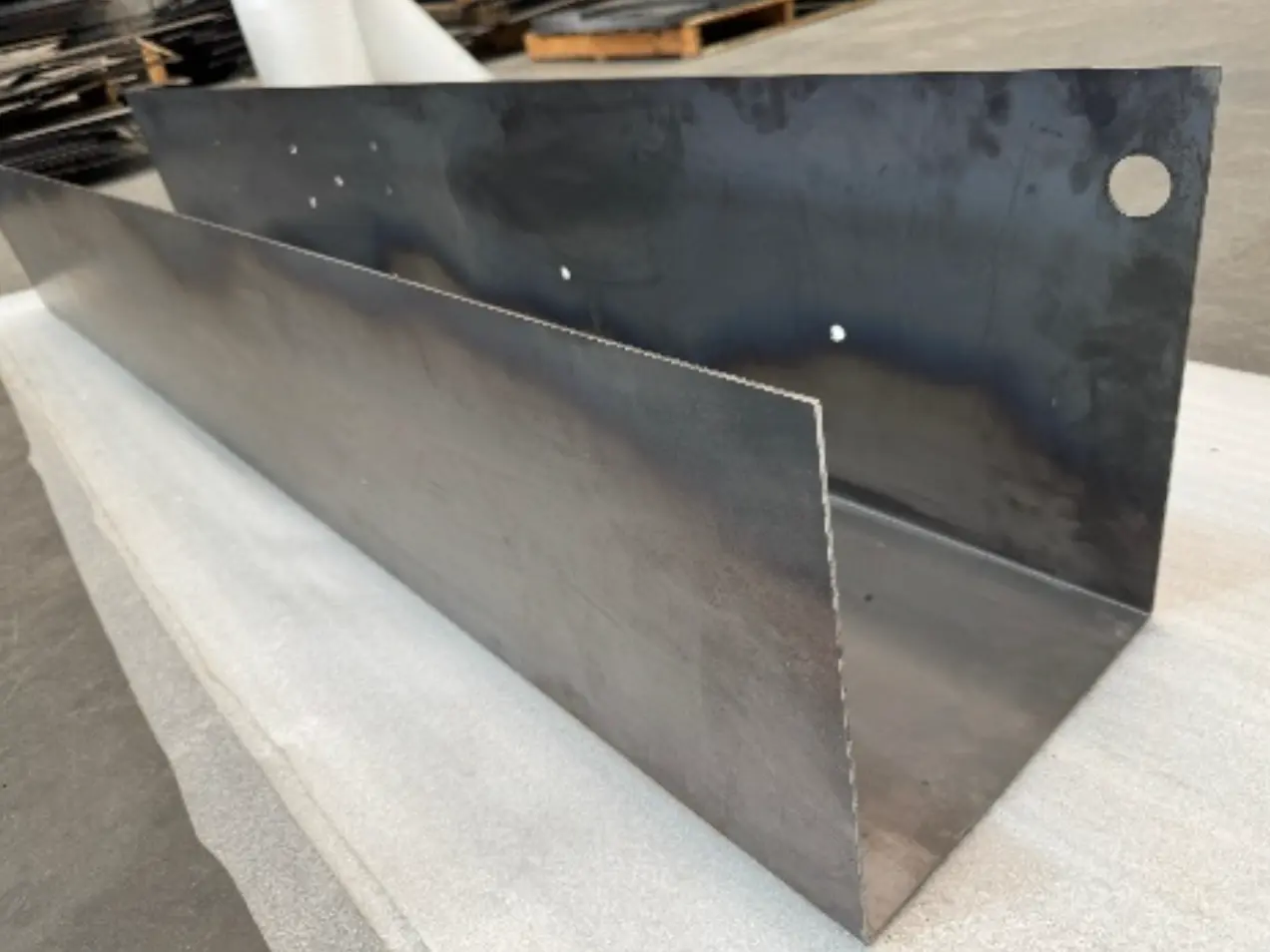

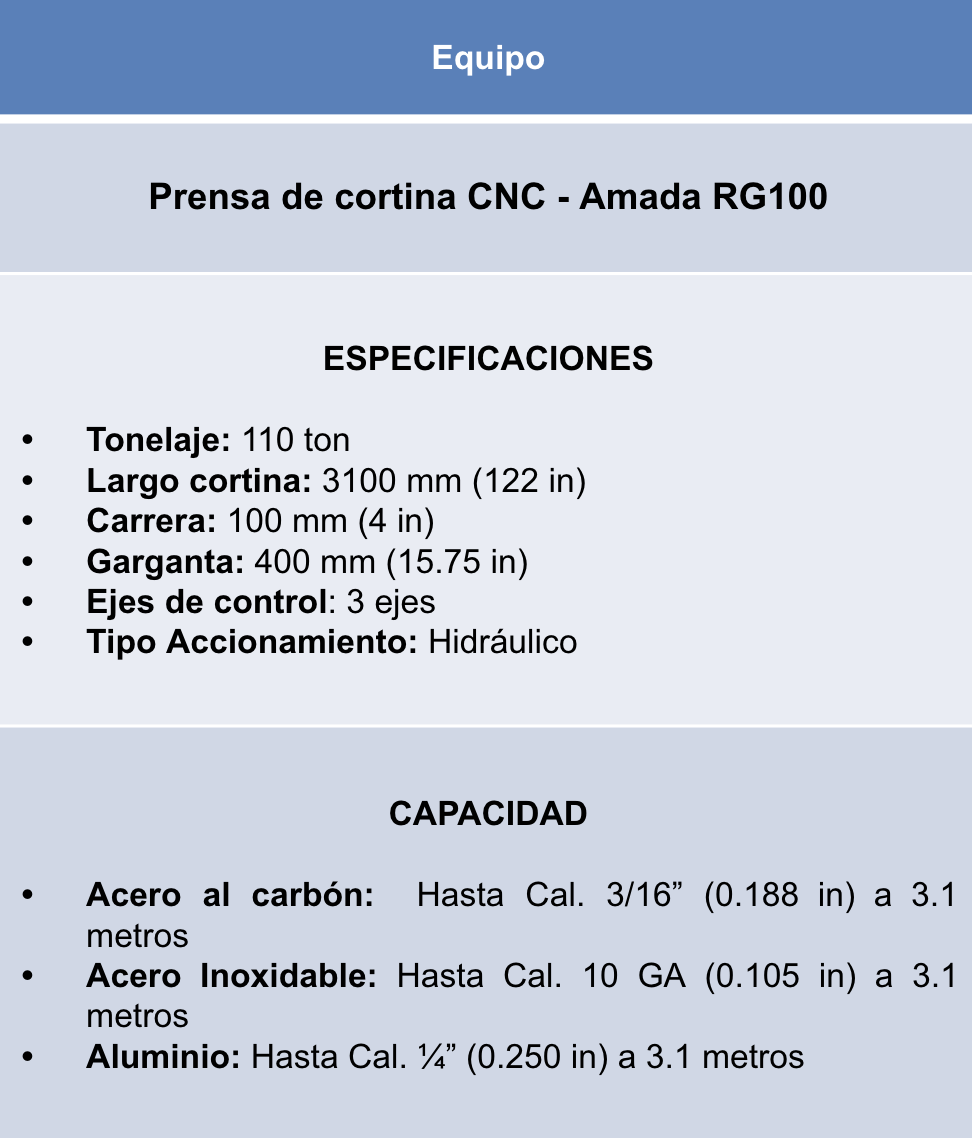

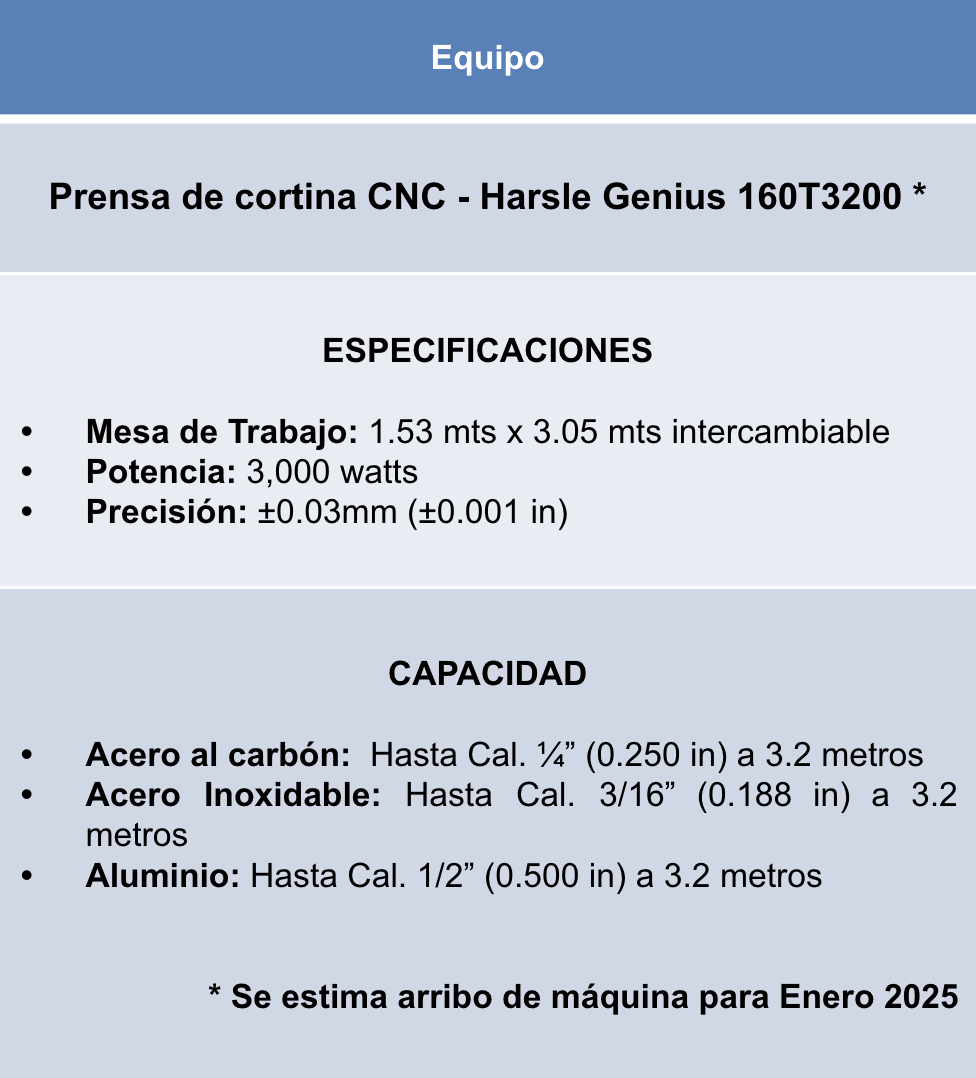

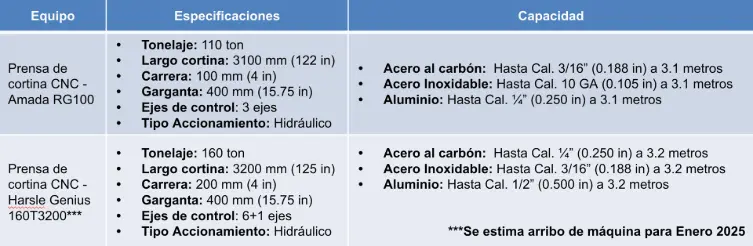

SHEET METAL FOLDING

SERVICES

We turn ideas into quality solutions, adapting to various industries with a commitment to excellence, innovation, and punctuality.

The 3-meter CNC presses with up to 100 tons of force allow us to bend different types of materials, whether for prototypes or for high-demand products.

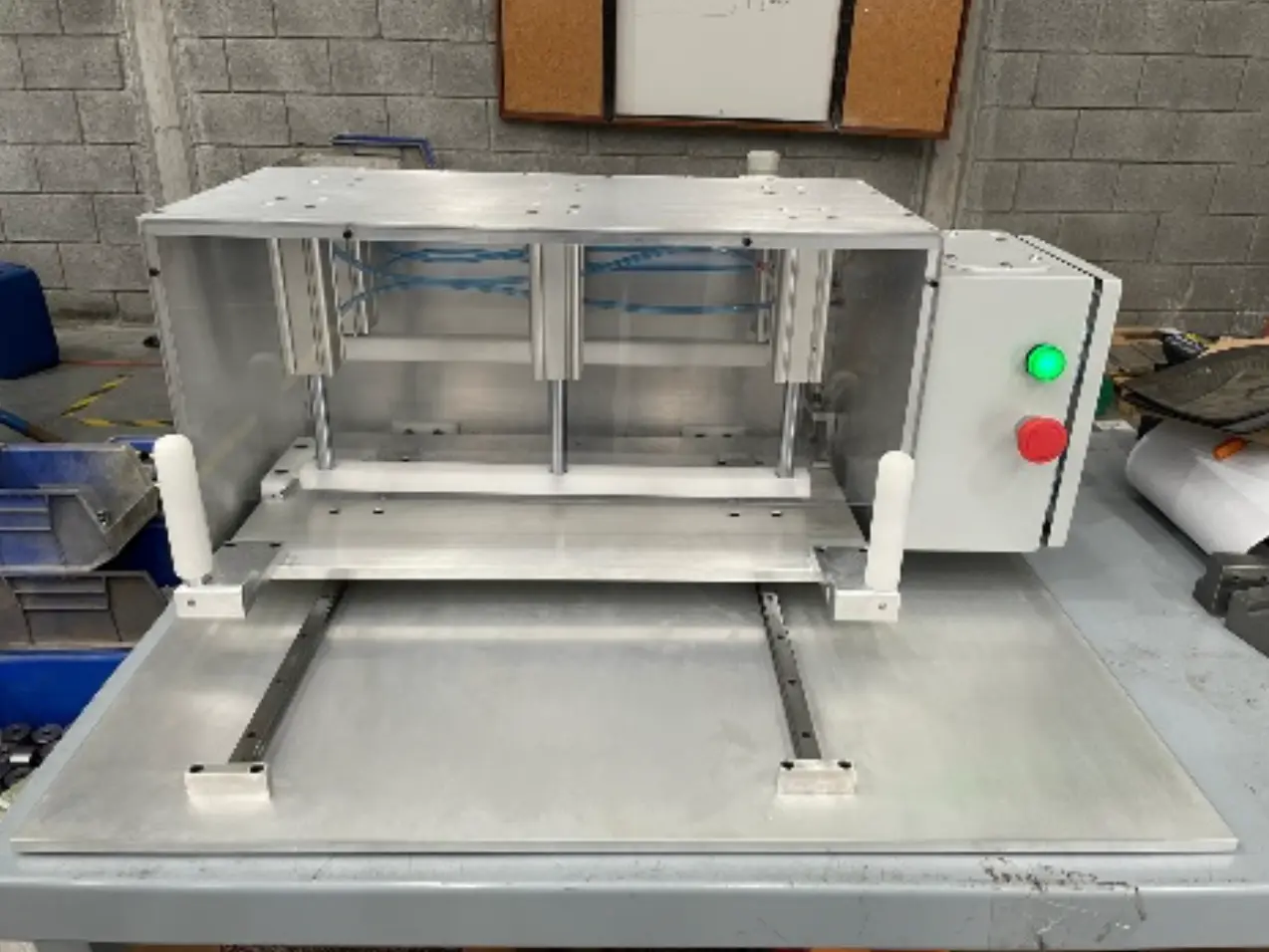

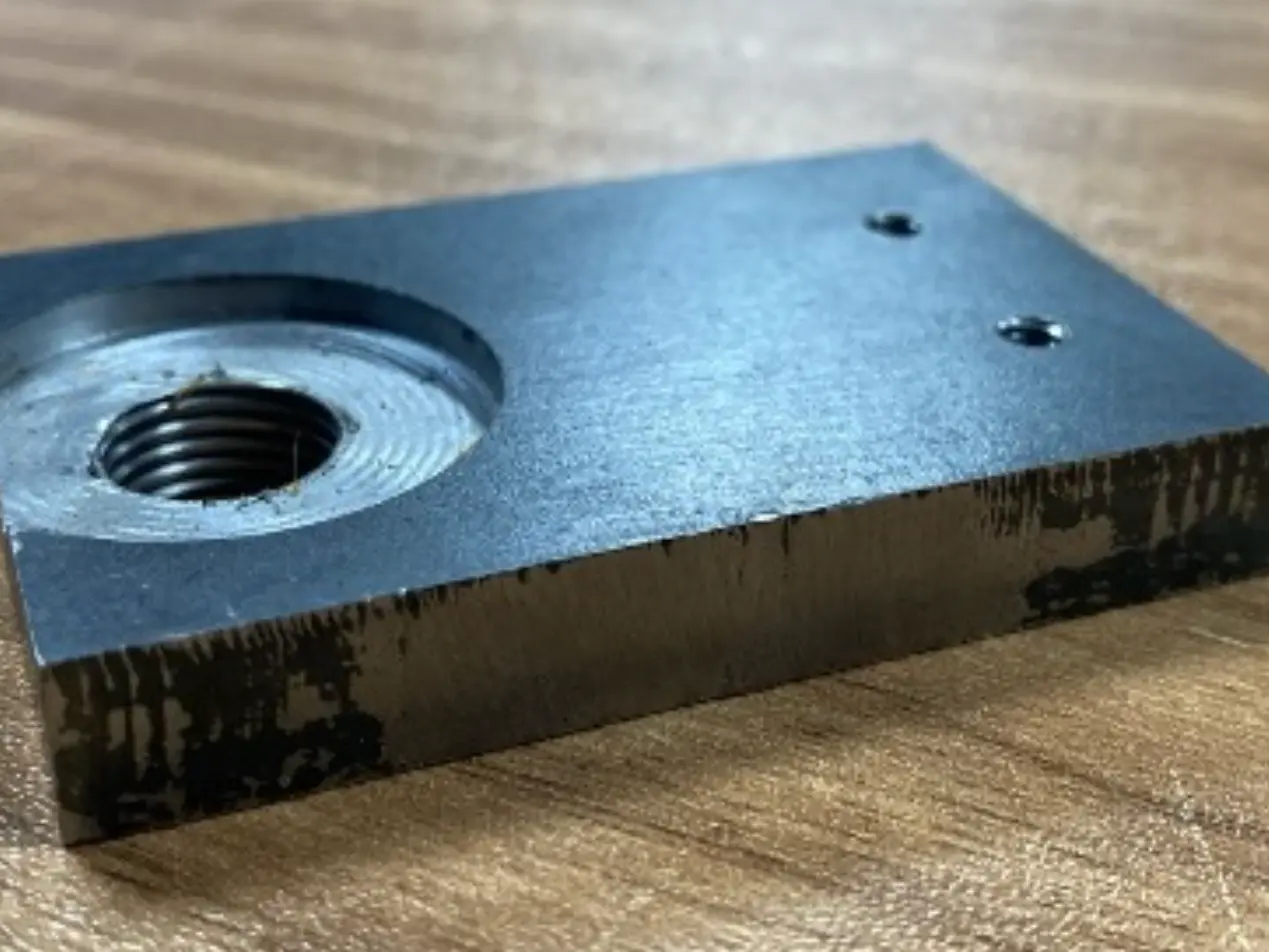

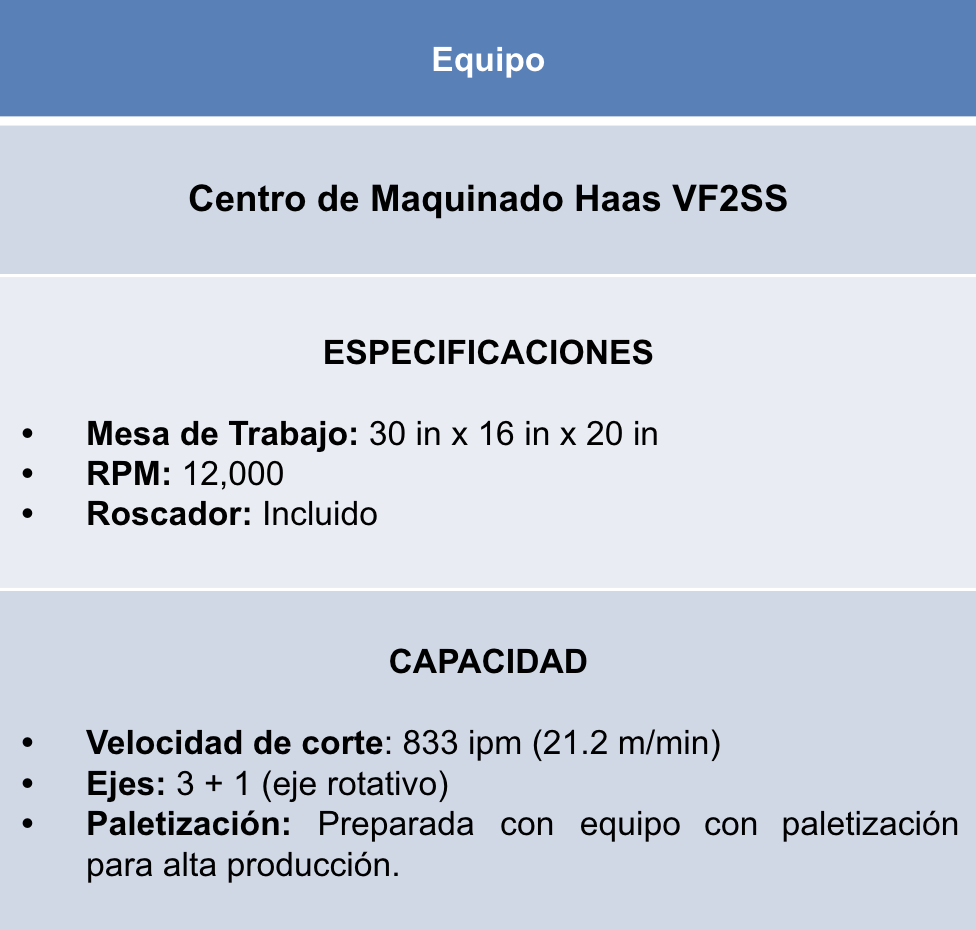

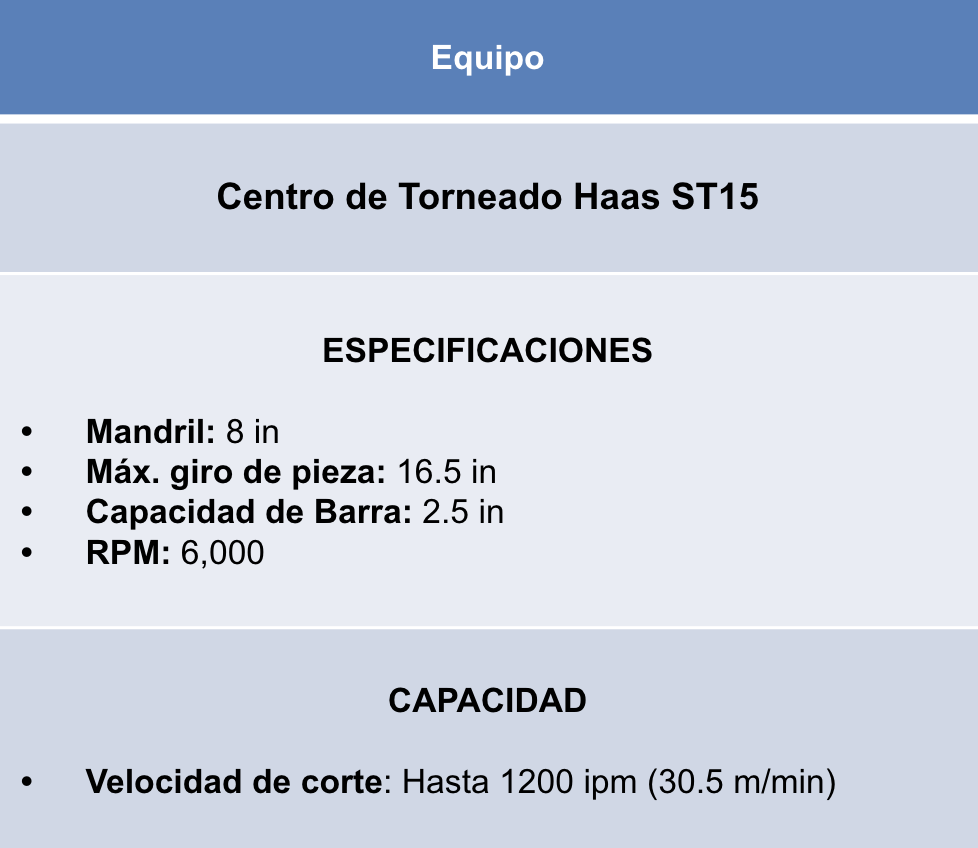

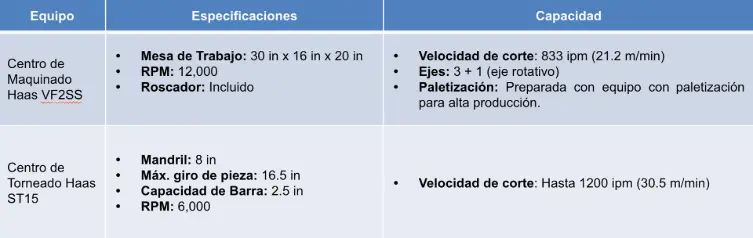

CNC TURNING AND MACHINING

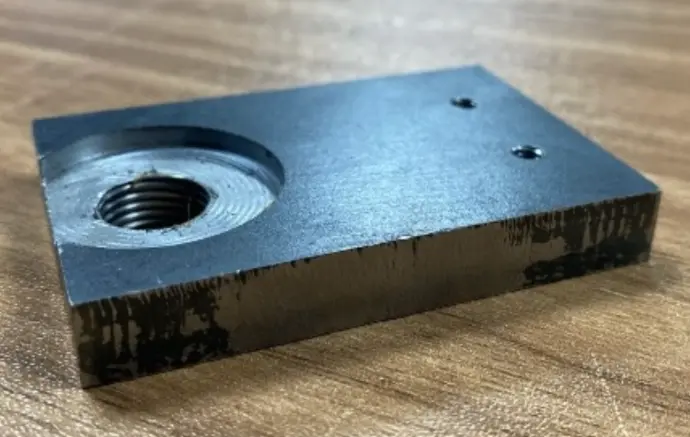

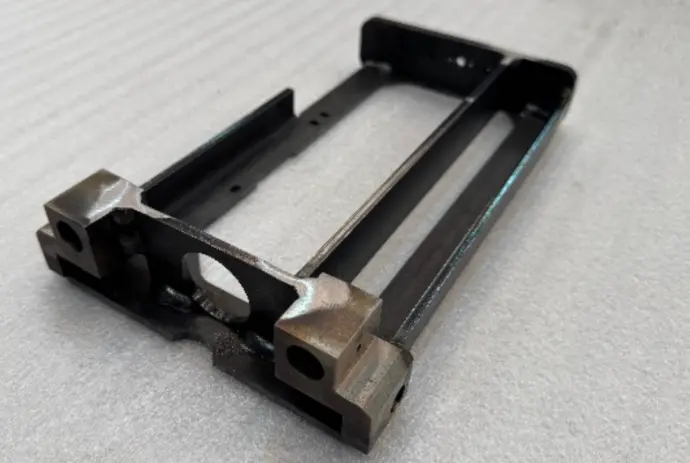

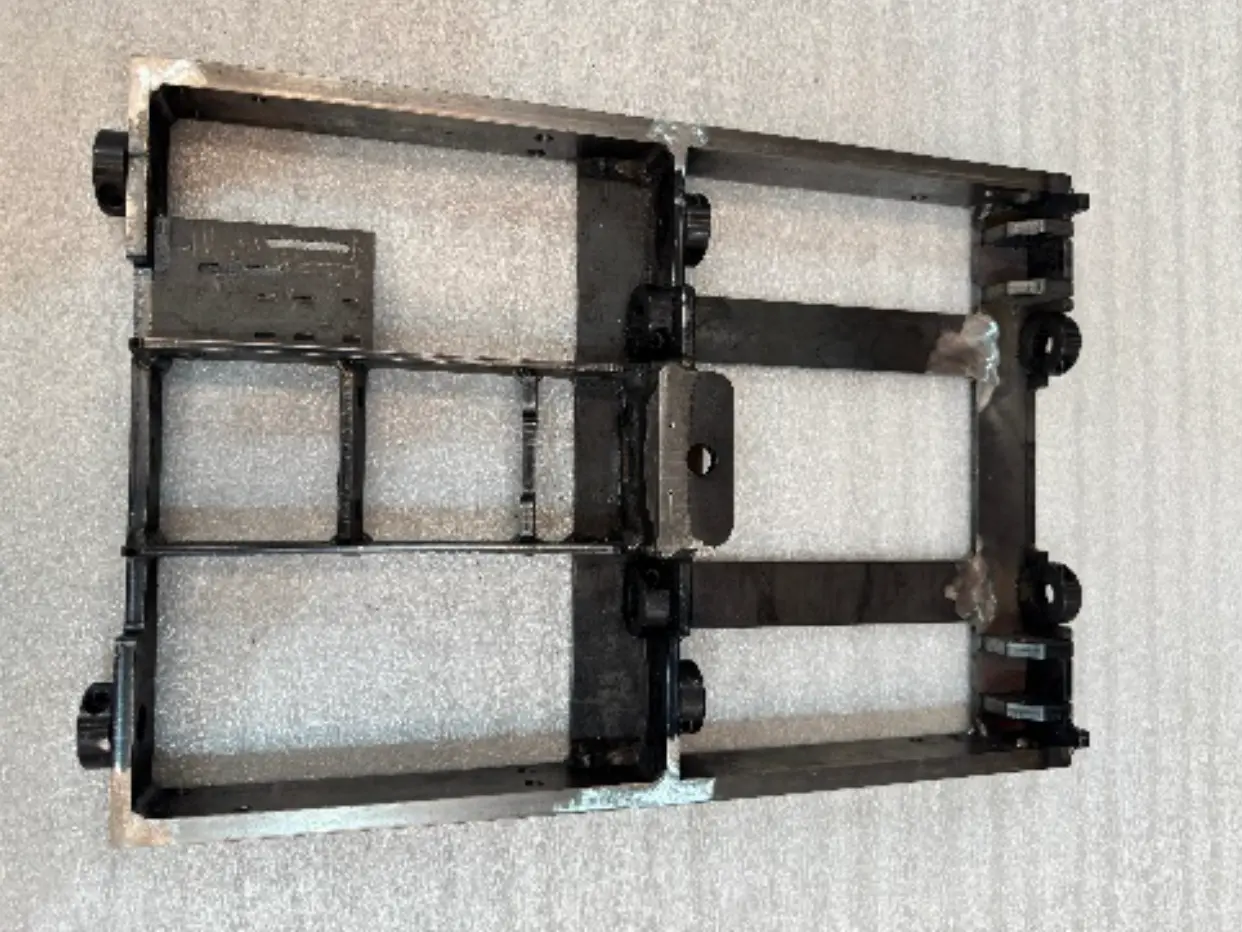

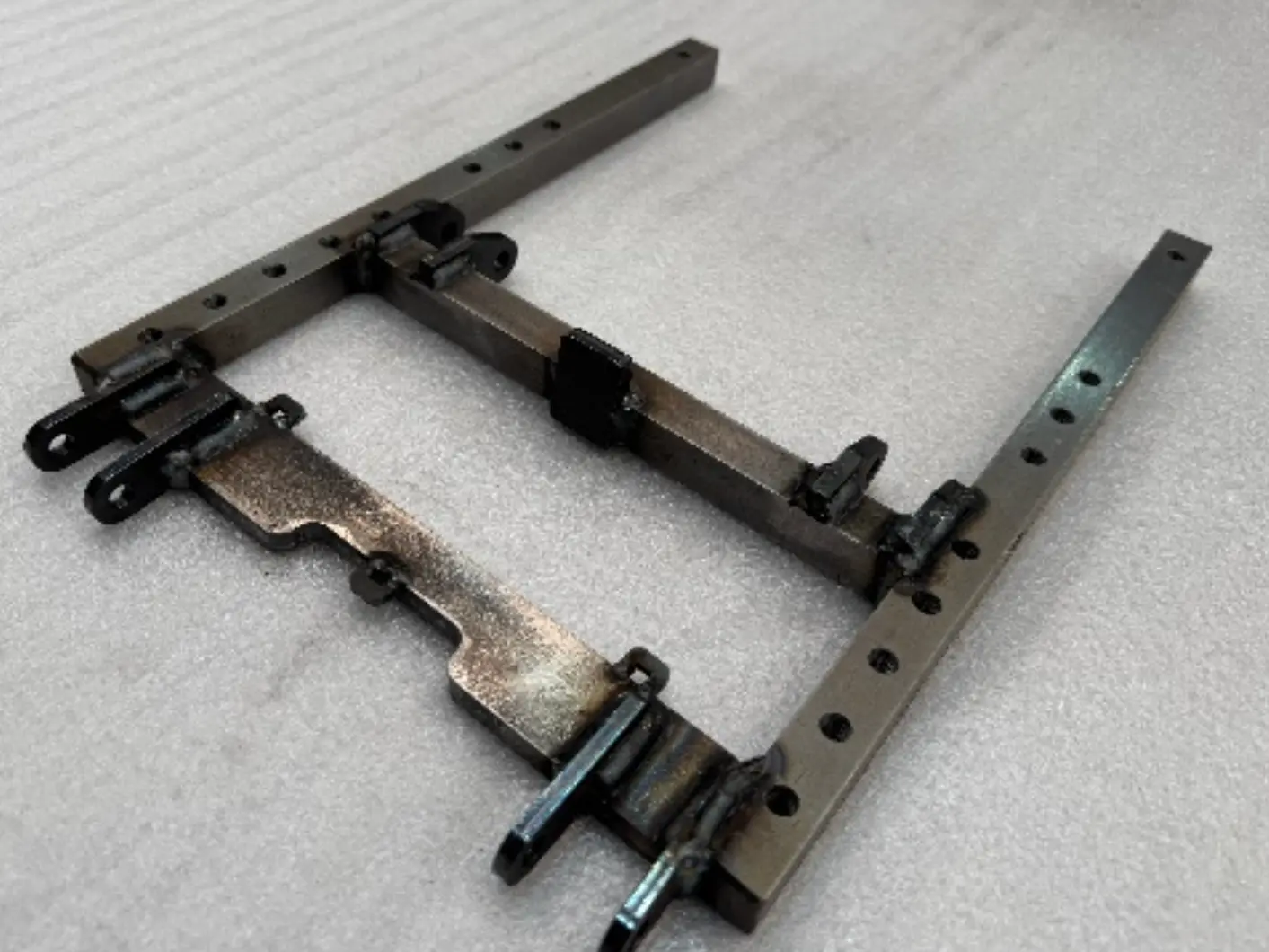

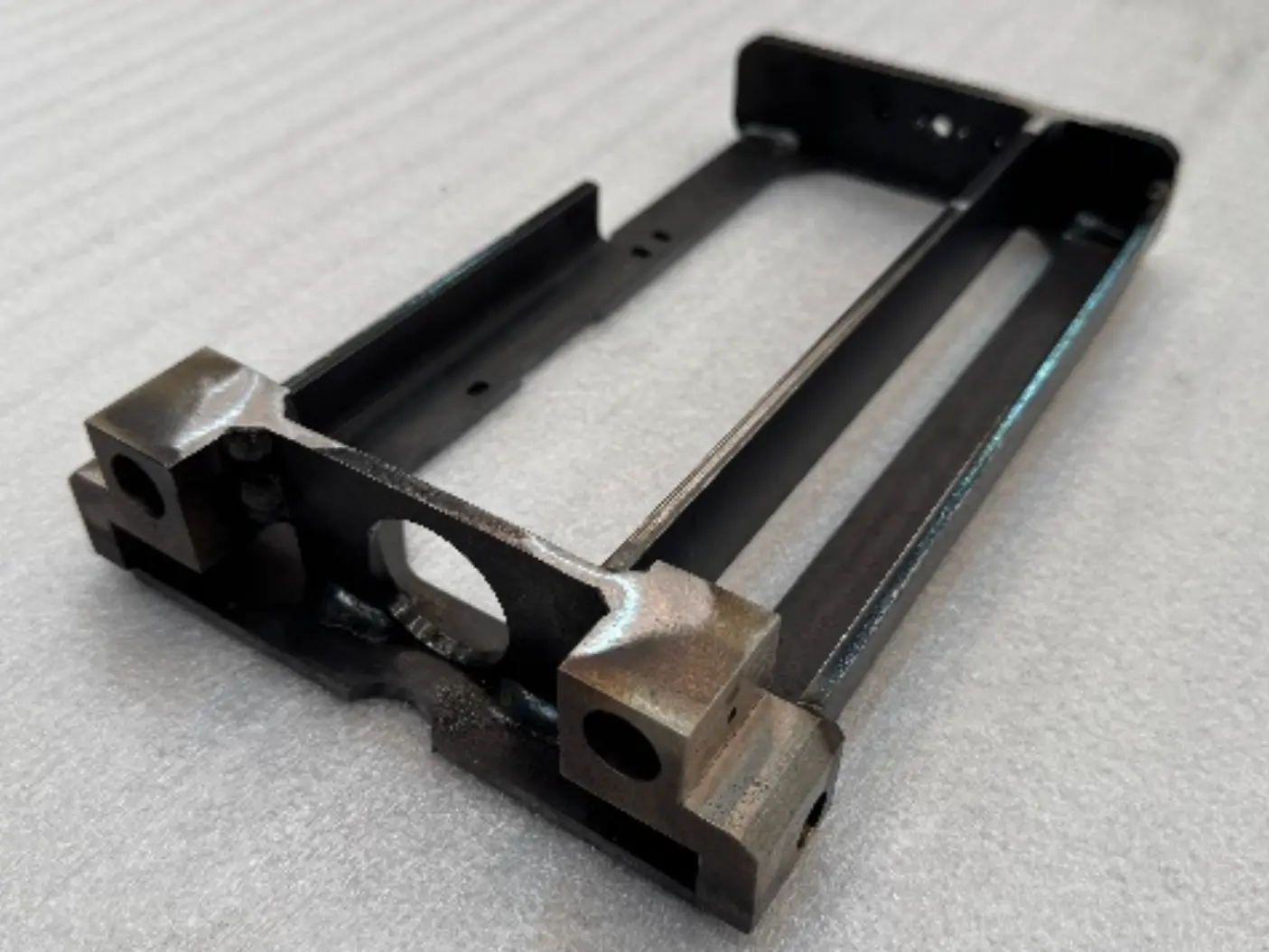

We have experience in the manufacturing of machined and turned parts from different types of materials such as steel, inconel, aluminum, engineering plastics, among others. We have state-of-the-art CNC equipment with high-speed 3 and 4 axis capabilities. We specialize in high-speed machining and designs of special quick-change fixtures developed by our Engineering team to optimize process times, thereby improving reaction time. The experience of our team has led us to design processes for high-demand parts, testing equipment such as soldering pallets for electronic boards, plastic injection molds, extrusion molds, assembly or holding devices, prototypes, among others.

Nos especializamos en maquinados de alta velocidad y diseños de sujeciones especiales de cambio rápido desarrollados por nuestro equipo de Ingeniería para optimizar los tiempos de proceso, mejorando así el tiempo de reacción.

La experiencia de nuestro equipo nos ha llevado a diseñar procesos para partes de alta demanda, equipo de prueba como pallets de soldadura de tablillas electrónicas, moldes de inyección de plástico, moldes de extrusión, dispositivos de ensamble o sujeción, prototipos, entre otros.

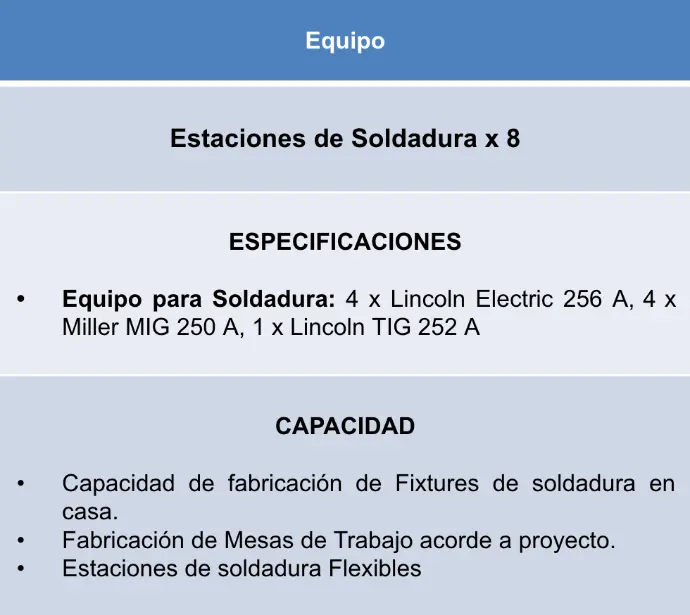

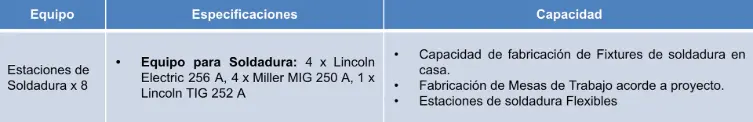

MIG/TIG WELDING

Soldadura MIG/TIG para ensambles de estructuras de Acero y productos estéticos de Acero Inoxidable y aluminio. Contamos con soldadores con amplia experiencia y con Robot de última tecnología para procesos de alto volumen.

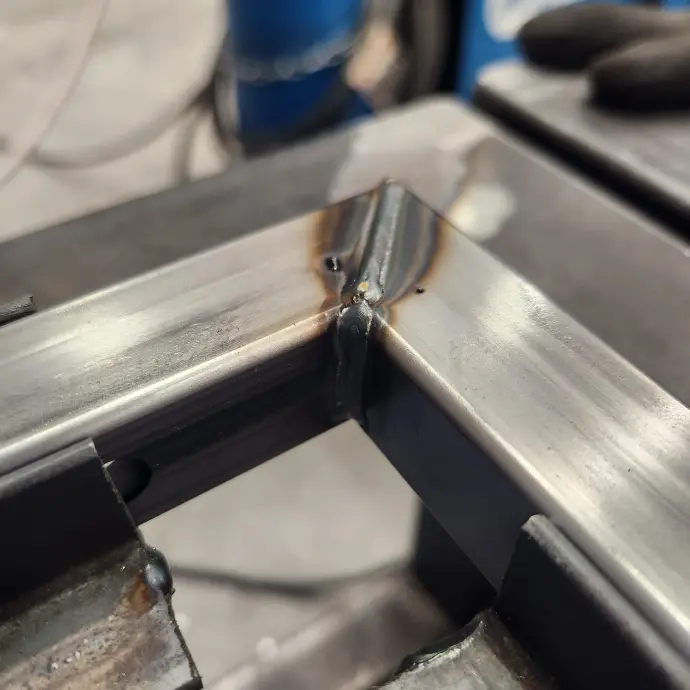

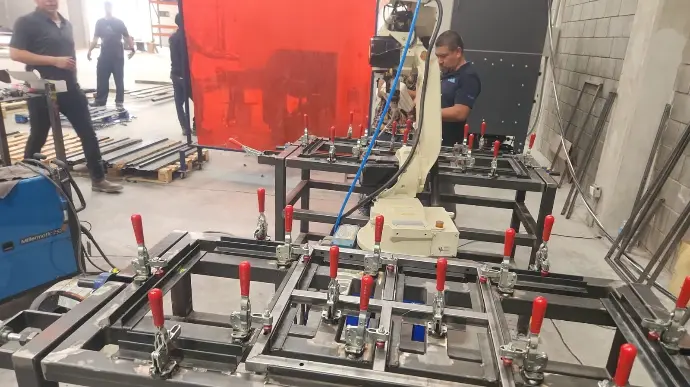

MIG/TIG welding for assembling steel structures and aesthetic products made of stainless steel and aluminum. We have highly experienced welders and state-of-the-art robots for high-volume processes. We have OTC brand robotic arms to ensure precision and quality in every welding wire. The repeatability and reliability of these machines help us achieve large quantities for high-demand products. In addition, our engineering team is equipped with the best tools to design Fixtures for high-volume production in a simple and efficient manner.

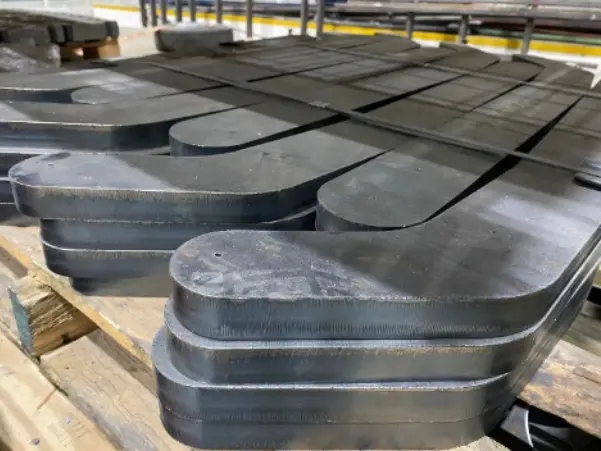

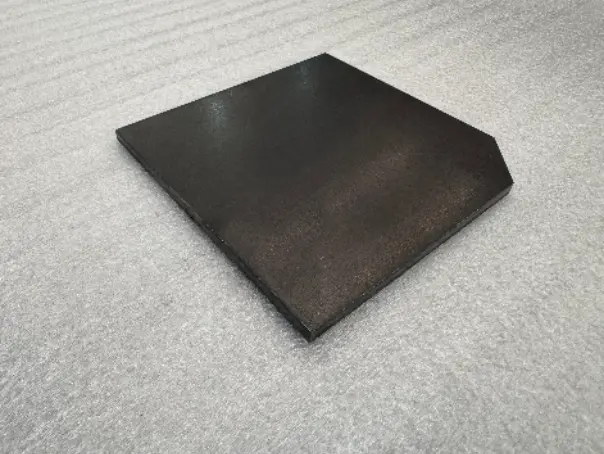

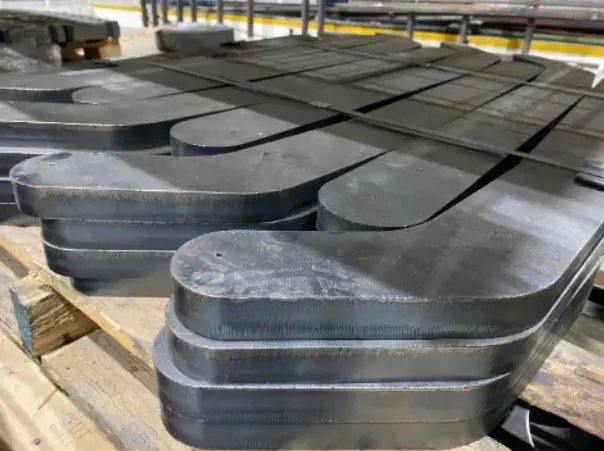

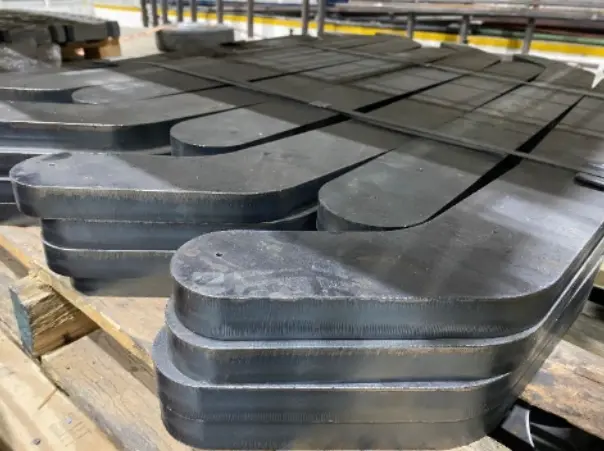

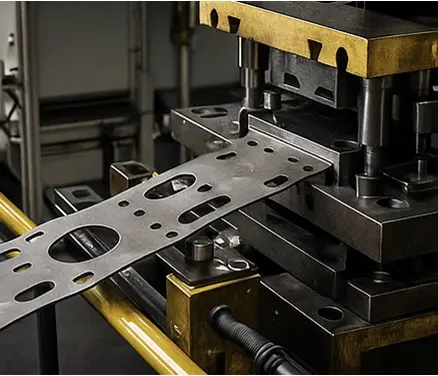

STAMPING

At CB Metal Fab, we offer high-precision stamping services, ideal for high-volume manufacturing of metal parts. We use mechanical presses and progressive dies to transform steel sheet or plate into complex components, meeting industrial and automotive specifications. Our process includes: Cutting, punching, and forming in a single operation High repeatability and production speed Integration with automatic feeders for maximum efficiency. Whether for flat parts or complex embossing, we have the capacity and tooling necessary to manufacture more than 1 million parts per year with consistent quality.