TILT SYSTEM FOR ELECTRIC WHEELCHAIRS

WHEELCHAIR TILT SYSTEM

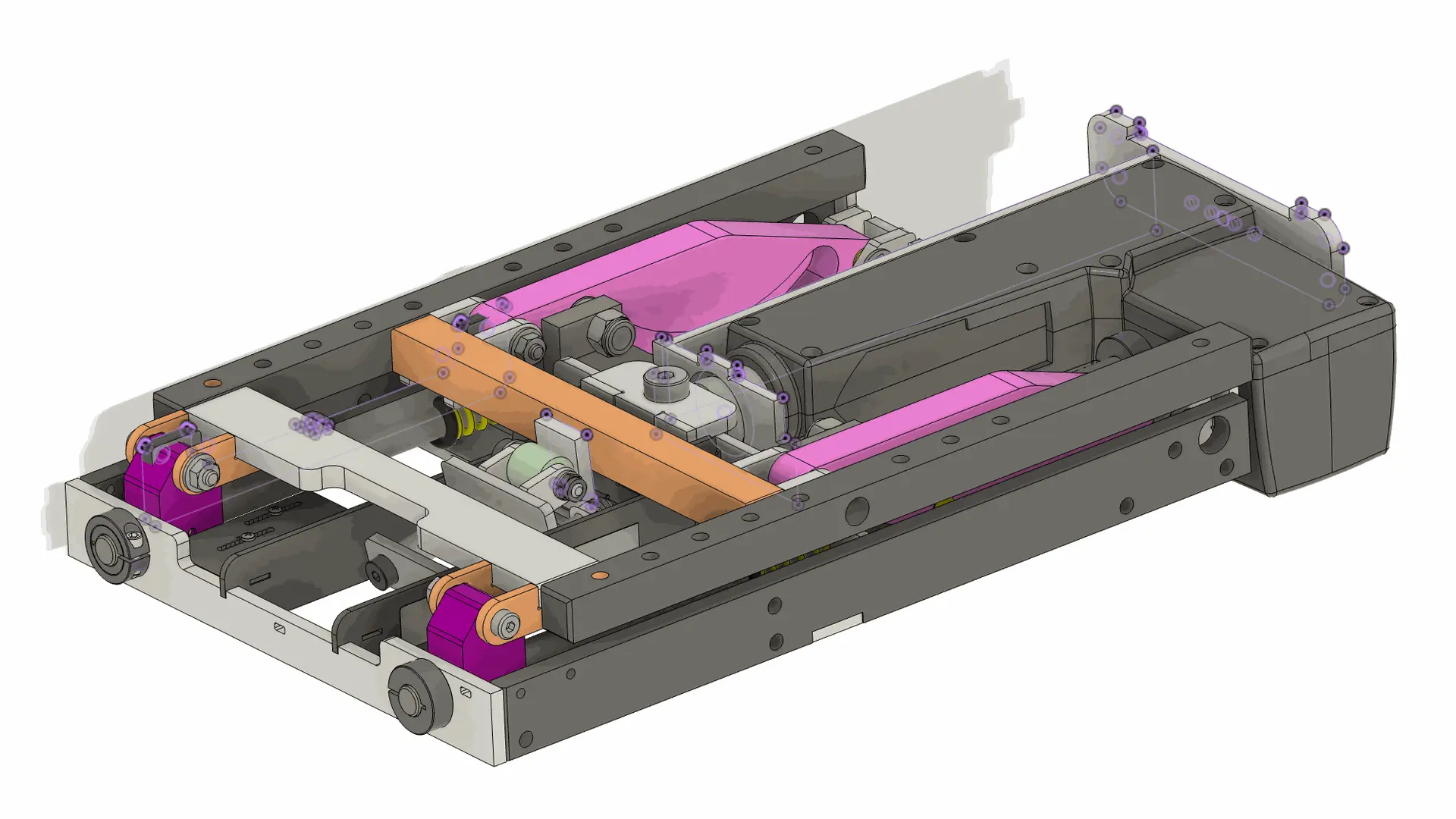

Our client, a Canadian manufacturer of high-end electric wheelchairs, needed to develop an optional component that would allow users to recline their bodies safely and accurately. This project required the utmost precision to ensure the proper functioning of the mechanism.

CONTEXT

The client is a leader in the manufacturing of electric wheelchairs focused on the comfort and functionality of users. The Tilt product is an essential component that allows users to adjust the tilt of the chair and redistribute their weight, providing them with greater comfort and support. Precision in assembly was key due to the mechanical nature of the component, activated by an electric piston.

CONTEXT

The client is a leader in the manufacturing of electric wheelchairs focused on the comfort and functionality of users. The Tilt product is an essential component that allows users to adjust the tilt of the chair and redistribute their weight, providing them with greater comfort and support. Precision in assembly was key due to the mechanical nature of the component, activated by an electric piston.

DEVELOPMENT

The project presented several challenges, especially in terms of precision and assembly. The manufacturing of Tilt involved a combination of multiple processes, such as laser cutting, CNC machining, sheet metal bending, manual welding, painting, and assembly. Welding was one of the most critical aspects due to the extremely tight tolerances required by the design. To overcome these challenges, we developed special jigs that allowed us to ensure consistency and precision in each of the subcomponents, ensuring the proper fit of the entire mechanical system.

DEVELOPMENT

The project presented several challenges, especially in terms of precision and assembly. The manufacturing of Tilt involved a combination of multiple processes, such as laser cutting, CNC machining, sheet metal bending, manual welding, painting, and assembly. Welding was one of the most critical aspects due to the extremely tight tolerances required by the design. To overcome these challenges, we developed special jigs that allowed us to ensure consistency and precision in each of the subcomponents, ensuring the proper fit of the entire mechanical system.

DELIVERY

The Tilt component was successfully delivered, meeting the demanding specifications of our client. The results were outstanding in terms of precision and the operation of the mechanism. The client was extremely satisfied with the quality of the product and highlighted our team's commitment to overcoming the technical challenges of the project.